Empowering Students with Robotics and 3D Printing

At the MSA | Münster School of Architecture, the future of architectural education takes shape through an innovative course in robotics and 3D printing. This program bridges the gap between parametric design and digital fabrication, giving students hands-on experience in controlling how their designs are brought to life. In a world facing challenges like the skilled labor shortage, modular construction, and digital building, these skills are essential for the architects of tomorrow.

From Design to Digital Fabrication

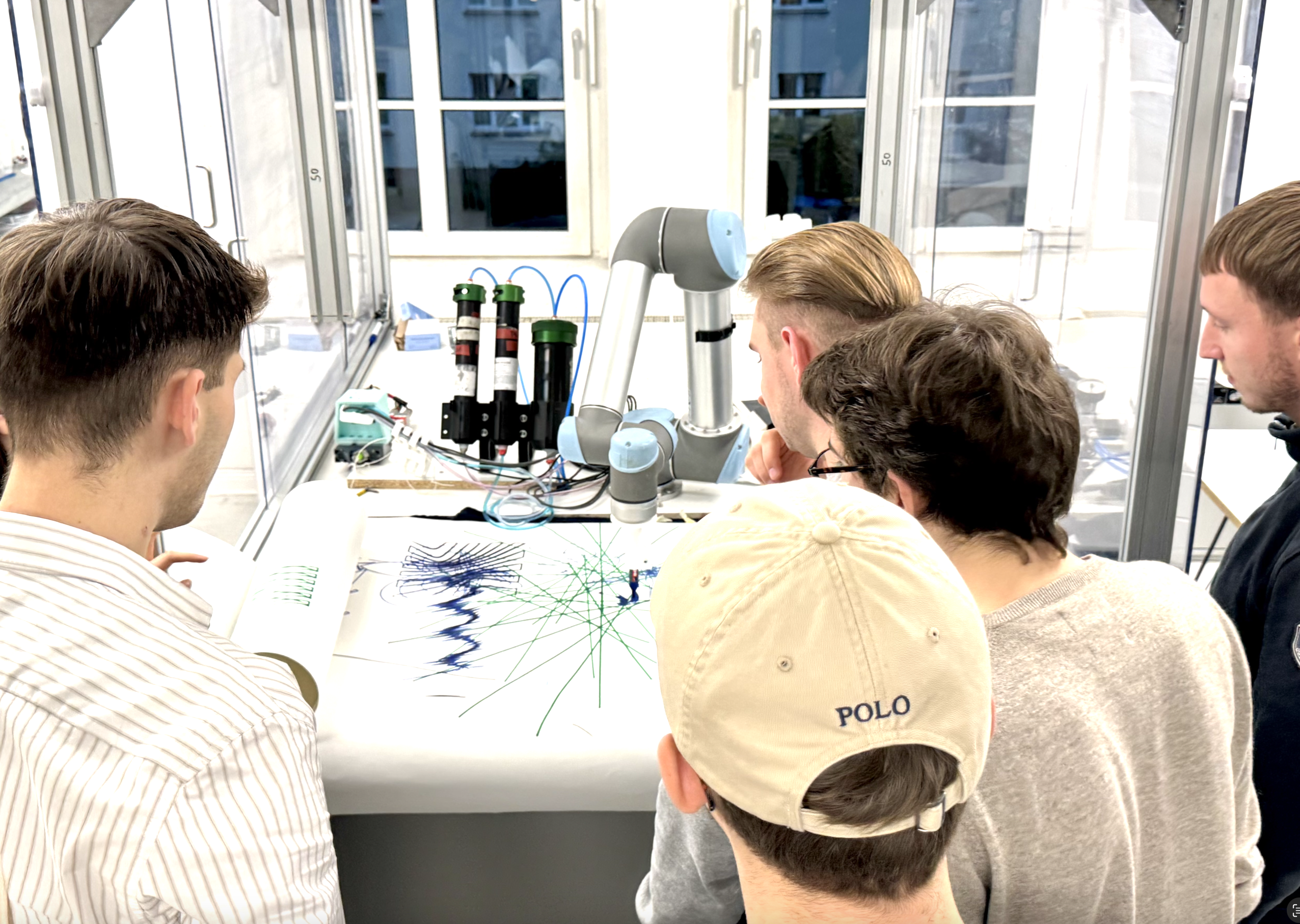

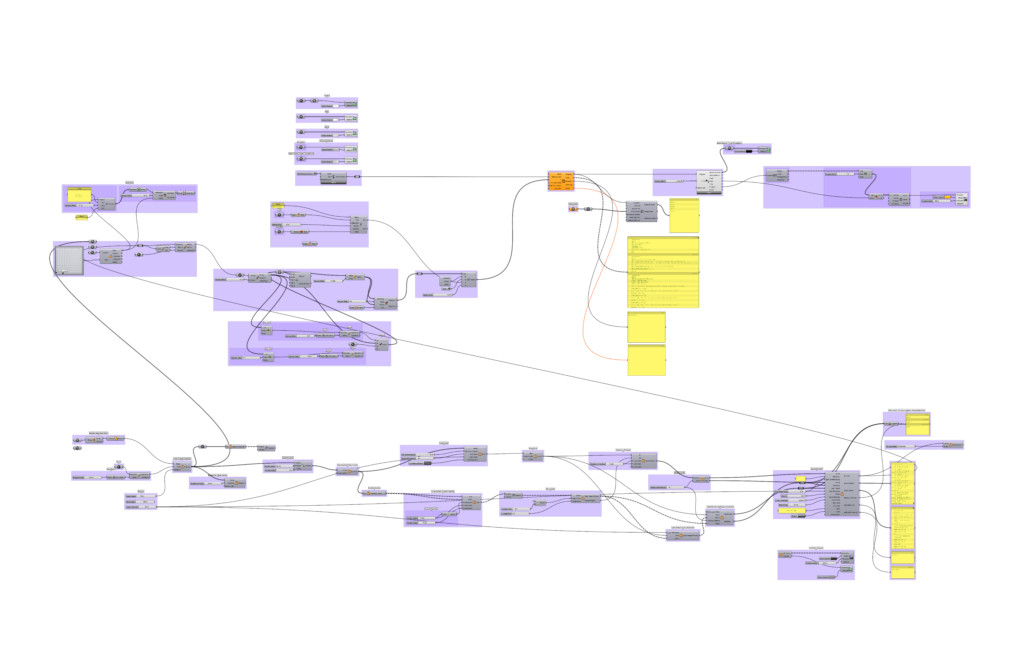

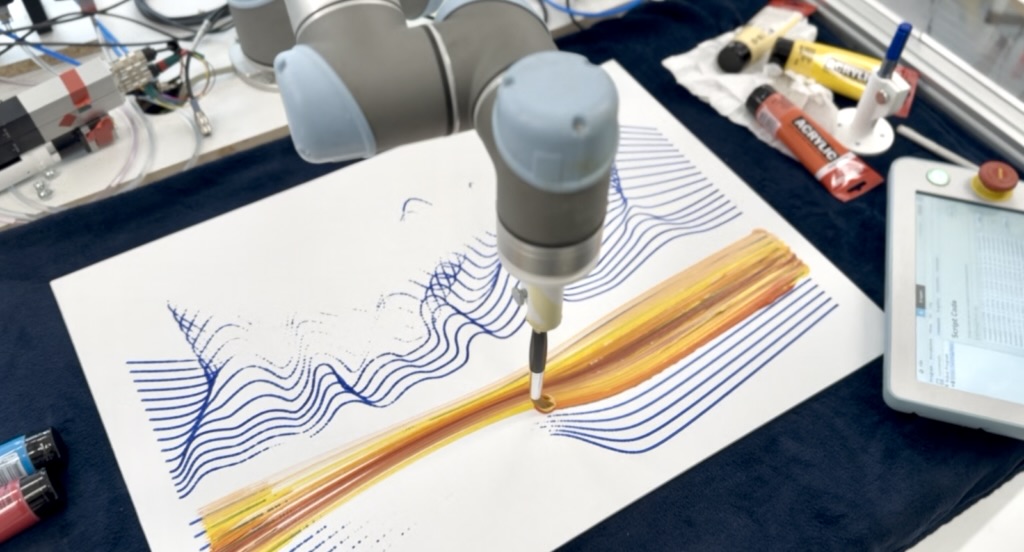

The course begins with an introduction to parametric design using tools like Rhino 3D and Grasshopper, equipping students with the ability to create adaptable, data-driven geometries. They then transition into robotics, where they work with the Universal Robot UR5, mastering foundational skills such as robotic plane transformations, toolpath planning, and motion control. By engaging in exercises like 2D drawing with a pen, students learn how to translate their designs into robotic instructions.

The final phase immerses students in robotic additive manufacturing. Using larger robotic systems as the Kuka KR120, they bring their parametrically designed geometries into the third dimension, experimenting with various tools, angles, and trajectories. This hands-on experience enables students to fabricate complex 3D objects, such as intricate modular components for modern construction methods.

Why It Matters for Architects

In today’s architectural landscape, understanding digital fabrication is no longer optional—it’s a necessity. By controlling how designs are fabricated, architects can directly influence construction efficiency, material optimization, and adaptability. This skillset is crucial for addressing modern challenges like the labor shortage, the rise of modular construction, and the growing demand for sustainable, digital building practices.

The course at the MSA ensures students leave with more than theoretical knowledge—they develop a practical, technical skillset that allows them to lead in the design and execution of advanced building systems.

Highlights

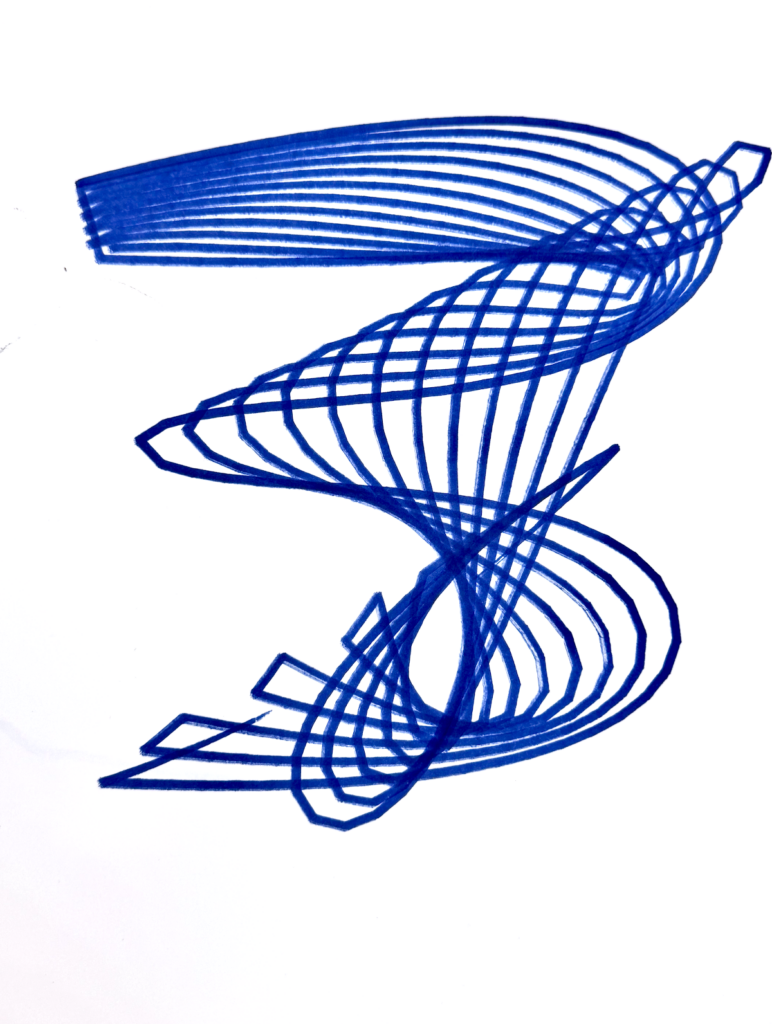

The course, titled “Parametric Design to [Robotic [Additive]] Manufacturing,” showcases students actively engaging with digital tools and robotic systems. One notable project includes the work of Desislava Paneva, a student who, in a similar course, under the guidance of Adam Pajonk, M.A., explored brush-based robotic fabrication. Her project highlights the creative potential of blending artistic vision with technical precision.

In the images from the course, students are shown working through each stage of the process, from conceptualizing parametric designs to using robotic arms for additive manufacturing. These snapshots capture the energy and innovation driving this essential area of architectural education.

Preparing for the Future of Building

The course at the MSA exemplifies the integration of design, robotics, and digital fabrication in architectural education. By empowering students with these tools, the program prepares them to redefine the construction industry and address its evolving demands. Whether creating modular systems or mastering the intricacies of robotic manufacturing, students are equipped to lead the way in a digitally driven future.